PRODUCT DESCRIPTION

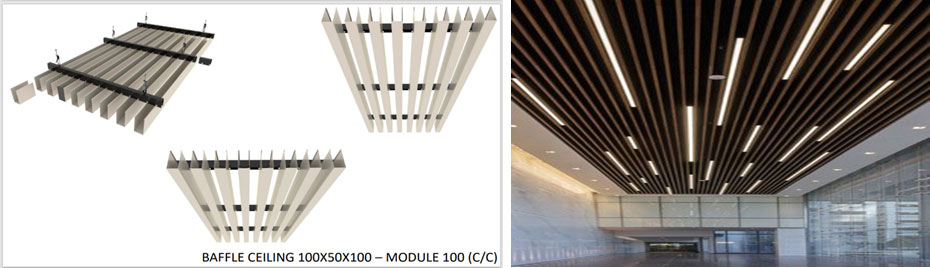

The Oculus® U Shaped baffle ceiling is an innovative idea of ceiling, baffle profiles consist a box or U-shaped profile of customized heights and widths, which provide an effective one directional visual, elegant line & amazing curtain kind of effects, also enables and open field of vision, good ventilation and air flow. The customize gap between panels make it more functional, three-dimensional and impressive. U-Baffle ceiling systems gives a floating, effect which attracts architects considerable design freedom, wide range of design options are available. U-Shaped baffles are available in widths of 25mm & 50mm with multiple customized heights i.e., 13mm, 15mm, 25mm, 50mm, 75mm, 100mm, 125mm & 150mm.

APPLICATIONS

It enables and open fixed vision, good ventilation and air flow the connection lines are bright and clean for long. Ventilation & smoke extraction to be easily realized through the gaps of baffles. Easy accessibility to the plenum. Baffles panels highly used in airport areas, metro stations, waiting areas, conference rooms and meeting rooms.

SPECIFICATIONS

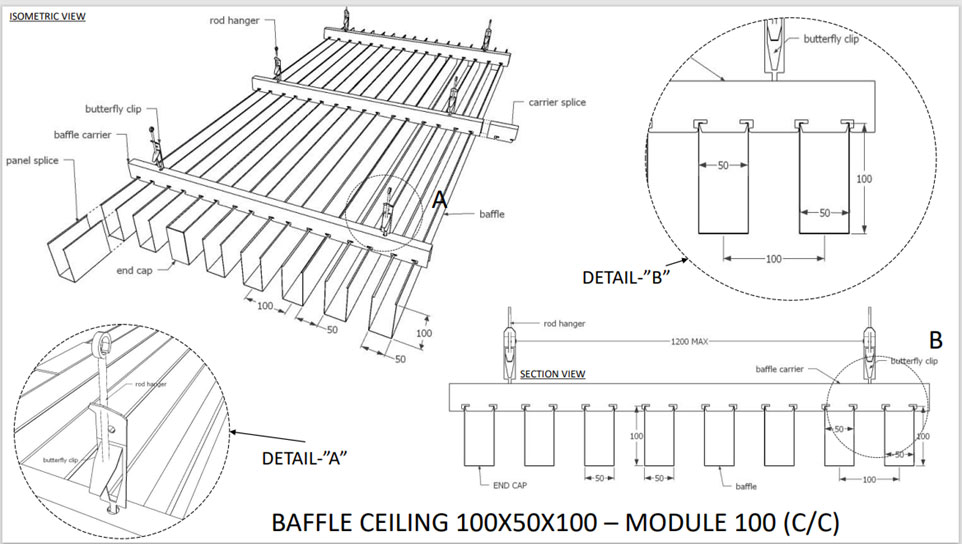

Oculus® make customized (height & width) Baffles are roll formed from 0.45mm, 0.5mm thick galvanized steel & 0.65mm, 0.7mm aluminium, powder coated & coil coated, baffles fixed on 20mm wide and 45mm deep 0.6mm galvanised or 0.7mm aluminium carriers. Carriers are suspended from the roof by 4mm diameter rod with an adjustment spring (butterfly clip) it gives fixability to adjust the level of panels, Baffle panels are available of different widths i.e., 25mm & 50mm and heights i.e., 25mm,50mm,75mm,100mm,125mm,150mm, length up to 5000mm.

TECHNICAL DETAILS

PANEL – Oculus® baffles (25×50, 50×50, 75×50, 100×50, 125×50, 150×50, 25×25, 50×25, 75×25, 100×25, 125×25 & 150×25) panels with square edges (U-shape profile) and length up-to 5000mm. Available in 0.45mm & 0.5mm in galvanised steel (GI) and 0.65mm & 0.7mm thick in aluminium (AL).

POWDER COATING – 50-60 microns thick powder coating on exposed area & 20-25 microns powder coating on rear side.

COIL COATING – The durable polyester finish in a nominal thickness of 20 microns on exposed surface & 5-10 microns on rear side.

PERFORATION – 2.0mm dia. perforation with 7mm C/C diagonal pattern.

SUSPENSION – 4mm dia. GI Rod, Adjustment spring, panel splice for panel joint and carrier splice for carrier jointing, galvanized steel edge profile